An Intelligent Head

Adding the final touch! Safematic sets new standards in laboratory coating with its compact sputter head. Our SP-011 sputtering system is designed for high quality sputter deposition. See for yourself the smaller form factor and the numerous features that our engineers have packed into this head. The magnetron of the SP-011 sputter unit is designed for high power sputtering and for a broad range of coating materials. Our sputtering modules plug into our CCU-010 HV and CCU-010 LV coating systems and are immediately ready to go.

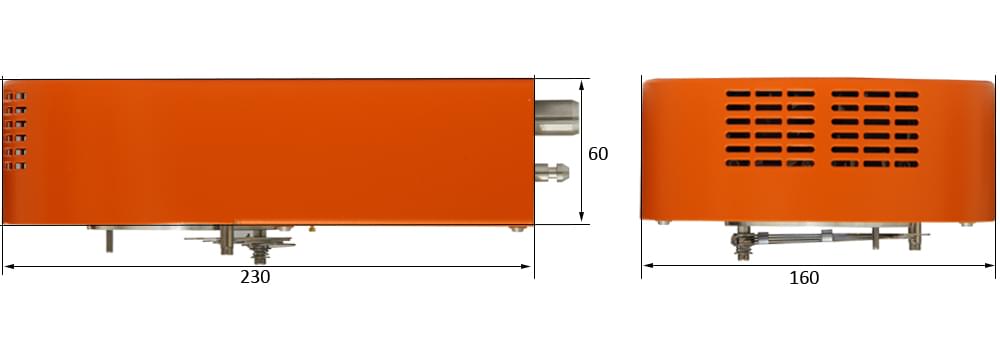

SP-011 Sputter Head

Art. No. 100012

Used with CCU-010 LV or CCU-010 HV vacuum coating systems.

Sputter coater, gold coater, table top coater, plasma coating, sputtering, sputter deposition